Building trust

Safety investigation indicates we’re in pretty good hands in face of re-do

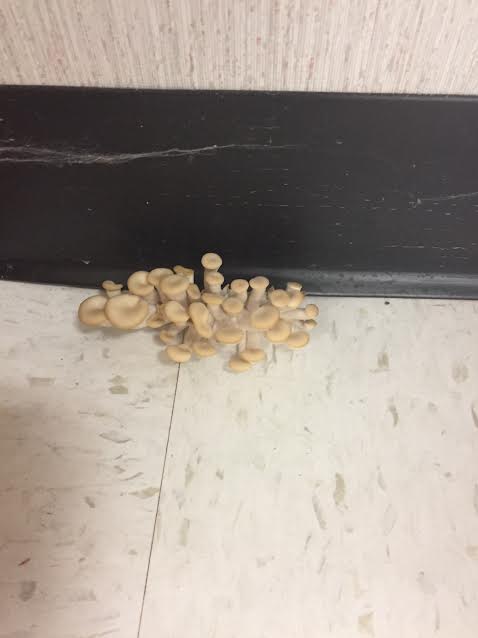

Photo courtesy of Debbie Larsen

Above are the infamous mushrooms that grew in T310 before they were taken care of.

May 31, 2017

By now, Spartans are jaded by construction talk. Although students have grown accustomed to the transient pathways and booming interruptions that define WS’s ambiance, it is still important to ensure the one of the highest tenets of FCPS’s mission are carried out: student safety.

A recent Oracle investigation into safety practices as our 50-year-old building undergoes renovation shows that almost every effort has been made to make sure our Spartan Community gets through the turmoil relatively unscathed.

The Occupational Health and Safety Act, signed into law in 1971, provides for suitable working conditions in an effort to curb workplace deaths and injuries. Several of its provisions apply to WS’s construction, from regulations specifically for construction zones to an instructor’s surroundings. Particular to this piece are those concerning both indoor and outdoor air quality, the presence of mold, and general dangers.

“The health and safety of students and staff is the project’s utmost concern,” said Becky Brandt, WS Construction Liaison.

A project of this scale has several components, notably Brandt, FCPS Office of Design and Construction Services (D&C), and Henley Construction.

All day, every day, there are two Field Representatives from D&C on site, JD Morgan and Jim Wyne. They monitor what happens during the day and walk the site regularly. For example, there’s no welding inside the building during school hours.

“This is a large undertaking…the lot has restrictions,” said Wyne. “[My role] is to maintain quality of work, so taxpayer dollars are well spent.” In the past, he has worked on projects at LBSS and Woodson, although this is of greater magnitude.

D&C also sends experts in safety, environmental conditions, and more for unannounced inspections. The caution tape that elongates fences, for example, are one safety requirement. Paths that are designated as appropriate for students are another standard.

“The D&C are experts with local and state regulations [in regards] to working conditions,” said Andy Muir, Director of Student Activities and lead administrator overseeing construction. “Several members also have ‘Progress Meetings’ every two weeks.”

Brandt is the primary link between the rhythm of school and frenzy of construction. She notifies management about pertinent events—major games, testing season, and other activities—so the crew can adjust accordingly. The contract states that noise will be minimized during times of high stakes.

“I share high points at school, such as when and where testing occurs, to avoid extreme noise,” said Brandt. “Many pieces fit into this puzzle—that’s how life is.”

There are also subcontractors that are called in for specific tasks, such as bricklaying, electrical work, and roofing. A secondary precaution is the fastidious sealing off of areas work is occurring in, which was necessary when concrete was laid in the wrestling room during spring break: air vents leading to the boys’ locker room were missed, leading to dust in the teacher’s office within. Once discovered, immediate notification led to a rapid fix.

Furthermore, few companies specialize in school construction because of the precautions and specificity required in labor. Russel Wade, WS Building Supervisor, is also a part of this “cooperative effort.”

“[We are in] a hyper-sensitive community. When something looks or feels bad—and I understand—parents want protection of what’s most treasured, [their] kids,” said Brandt.

This community is not afraid to voice opinions. One concern is incidents where concrete is being poured and the dust from the bag forms an ominous cloud that students walk and often cough through. In the building, fans are placed to drive away dust or smoke.

“Typically, we try to do best possible practices to control dust,” said Wyne. “[At a] site this large, it’s going to happen, so we do our best to control it.”

Dust is merely another component of renovation that students have learned to deal with. Tactics include shielding eyes, covering the mouth, or ignoring its presence.

“It seems like a lot of dust, especially when it’s windy,” said junior Thomas Milonovich. “It gets in your eyes and stuff. [But], it’s an active construction zone—there’s not much you can do.”

Wyne has a weekly meeting with the contractor; another agent from D&C also visits on a semimonthly basis. A recent qualm by WS community members is the trash left behind by construction workers. Food wrappers, articles of clothing, and more not only harm the school’s aesthetic, but also can prove detrimental if they are allowed to enter the watershed. Brandt also expressed frustration alongside parents, many of whom have voiced concerns.

“We take complaints seriously,” said Wyne. “[We have] asked construction workers to pick up trash—it’s an ongoing battle.”

Another question is air quality in the trailers, ranging from allergens to indoor air pollution. For senior Noza Janobilova, the episode began when her sixth period teacher asked the class whether her room had a “funny” scent. Based on student accounts, although the majority of them agreed, class went on as usual; it was not until a fire drill had occurred and Janobilova was mid-timed writing that she noticed her lips swelling. Soon, the scene intensified.

“[My skin] became itchy and broke into hives everywhere,” said Janobilova. “In the clinic, my throat swelled up; I was [given] an EpiPen injection and taken to the ER.”

The next day, Janobilova found more hives. But upon a visit to the doctor, she did not react to an allergy test and has no known triggers. This reaction could have been due to a natural allergen or a food her system was unaccustomed to; however, her doctor opined that her outbreak was likely a reaction to a substance in the air, possibly mold.

“[I was] very emotional and didn’t know what was happening,” said Janobilova. “My mom, overwhelmed, is concerned and alert.”

As a precautionary step and per doctor’s orders, Janobilova now carries an EpiPen to school, even though she does not have any known allergies.

The trailer situation, affectionately named Sparta, has created challenges for WS administrators and staff. One difficult quad, or a grouping of four classrooms within a learning cottage, is T310: this year, there have been issues with the flooring, air quality, and environs.

Mathematics teacher Debbie Larsen has often wondered what lies beneath the tile. Earlier this year, there was a mushroom patch growing under the classroom division, which indicates the presence of moisture and potentially harmful substances.

“[We] had lovely mushrooms growing,” said Larsen. “That was an issue. The county did come out and try to resolve but [growth] happened more than once—a little concerning.”

A team was swiftly sent to remove the mushrooms and the wall (in fact, WS custodians crawled under the quad to inspect conditions as well). Even with the changes, select tiles are peeling up and the floor itself is not level, but steeps upward and back down, a situation that has worsened through the year.

“Nobody wants to be in a moldy environment,” said Brandt. “We looked under [the trailer], did sub flooring, and put in a whole new wall as our response. We also re-addressed [it] when notified of a reoccurrence.”

This spring, indoor air quality became the real issue. Larsen has a sensitive palate, which is how she detected something was off. In early April, she decided to act on her senses.

“I noticed a bad taste [in my mouth] and wanted the air tested, so they did that,” said Larsen.

When test results came in, Larsen was glad she had listened to her body: Pre-cleaning carbon dioxide levels were two to three times above current, post-cleaning levels. Nevertheless, all were still well below OSHA’s “limit value.”

Regular human functions and combustion, especially in vehicles, contribute to increased CO2. In classrooms, the majority comes from exhaling in a tight setting. The fix is simple—ventilation with sufficient outdoor air flowing in. D&C sent workers to survey and subsequently service the air conditioning units with a rapid response time of one week.

“Precautionary steps maybe could’ve made a difference,” said Larsen.

Yet another incident was brought to her attention in January.

Larsen arrived at her trailer one morning, set to administer the precalculus midterm, and was overtaken by an oil or gas smell, both inside her trailer and surrounding it. She called administrators and asked to be moved, which she did for all periods that day. Other teachers felt unaffected.

The smell, emanating from a field adjacent to the trailer, was resolved throughout the day by a swiftly assembled cleaning crew.

Milonovich was one of the students testing the day of the smell, presumably from a gasoline spill. Although the move to a different classroom was prompt, it was a curve ball on the day of a high-stakes test.

“[The move] was bothersome…affected my focus. I was out of the test-taking mind-set, and it takes a little to get back,” said Milonovich.

This data points to the fact that FCPS’s response time when incidents do occur is impressive; the question remains, as to whether enough preventative steps are being taken. One certainty is that all members involved in the construction are capable and attentive—WS students are in good hands, even if the presence of an around 200 foot tall crane is disconcerting.

“[They] have been reactive to fixing issues,” said Muir. “Imagine the amount of work—they’ve done a good job [of] trying to separate the two [and ensure] the classroom is not affected.”